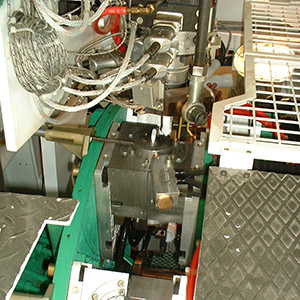

A range of 5 models from 2 to 10 molds:

2 molds Rotative blowing machine (SR2)

A two molds rotating machine with an output rate of 650 to 1 600 bottles an hour with capacities varying from 0.1L to 2L.

Max dimensions of containers:

- Closing strength: 1 T

- Volume: 2 000 cm3

- Height: 320 mm

- Diameter: 100 mm

4 molds Rotative blowing machine (SR4)

A four molds rotating machine with an output rate of 1 100 to 1 600 bottles an hour with capacities varying from 0.1L to 1L.

Max dimensions of containers:

- Closing strength: 1 T

- Volume: 2 000 cm3

- Height: 320 mm

- Diameter: 100 mm

6 molds Rotative blowing machine (SR6)

A six molds rotating machine with an output rate of 2 000 to 4 000 bottles an hour with capacities varying from 0.1L to 2L.

Max dimensions of containers:

- Closing strength: 1 T

- Volume: 2 000 cm3

- Height: 345 mm

- Diameter: 100 mm

8 molds Rotative blowing machine (SR8)

A eight molds rotating machine with an output rate of 2 600 to 5 200 bottles an hour with capacities varying from 0.1L to 1L.

Max dimensions of containers:

- Closing strength: 0,7 T

- Volume: 750 cm3

- Height: 195 mm

- Diameter: 100 mm

10 molds Rotative blowing machine (SR10)

A ten molds rotating machine with an output rate of 3 350 to 6 500 bottles an hour with capacities varying from 0.1L to 0.75L.

Max dimensions of containers:

- Closing strength: 0,7 T

- Volume: 750 cm3

- Height: 195 mm

- Diameter: 100 mm